Robots building circuit boards, BECAUSE RACECAR

We’re cranking out the RaceCapture/Pro MK2 production! Last week we built a large lot of telemetry module; this week we’re building panel after panel of RaceCapture/Pro MK2 units. Here’s Brent with the first official panel built!

Parts Feeders Always be Feeding!

All in all, Brent Scott, Kelley and Jeff were keeping the Lab warm along with the reflow solder oven. As typical with a new production run we had hiccups getting the pick and place machine fully dialed in. The secret? It’s all about the feeders. Here’s we’re either fixing a feeder or stringing a new reel of components onto one of the many feeders.

Once the machine was dialed in, we could stage the RaceCapture/Pro MK2 panels for assembly. In this configuration, we can build 4 RaceCapture/Pro boards at a time. Note the big “waffle tray” behind the panel- this is the parts tray for the main processor!

Solder Paste and Rework

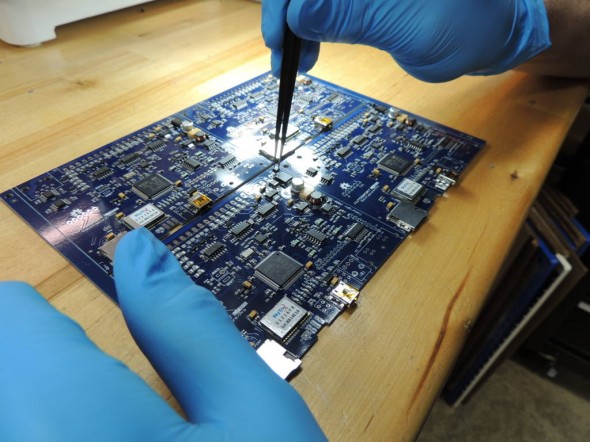

The first panel out of the pick and place (before solder reflow) gets a bit of re-work. Turns out the biggest challenge was getting that big processor soldered correctly. Too much solder paste = bridged pins, so getting the solder paste on the board perfectly will save tons of rework time.

Once we dialed in the process we’re able to get the boards cranked out. Here’s a few, staged up for the final through hole (bottom side) soldering process